Return

Print

Email

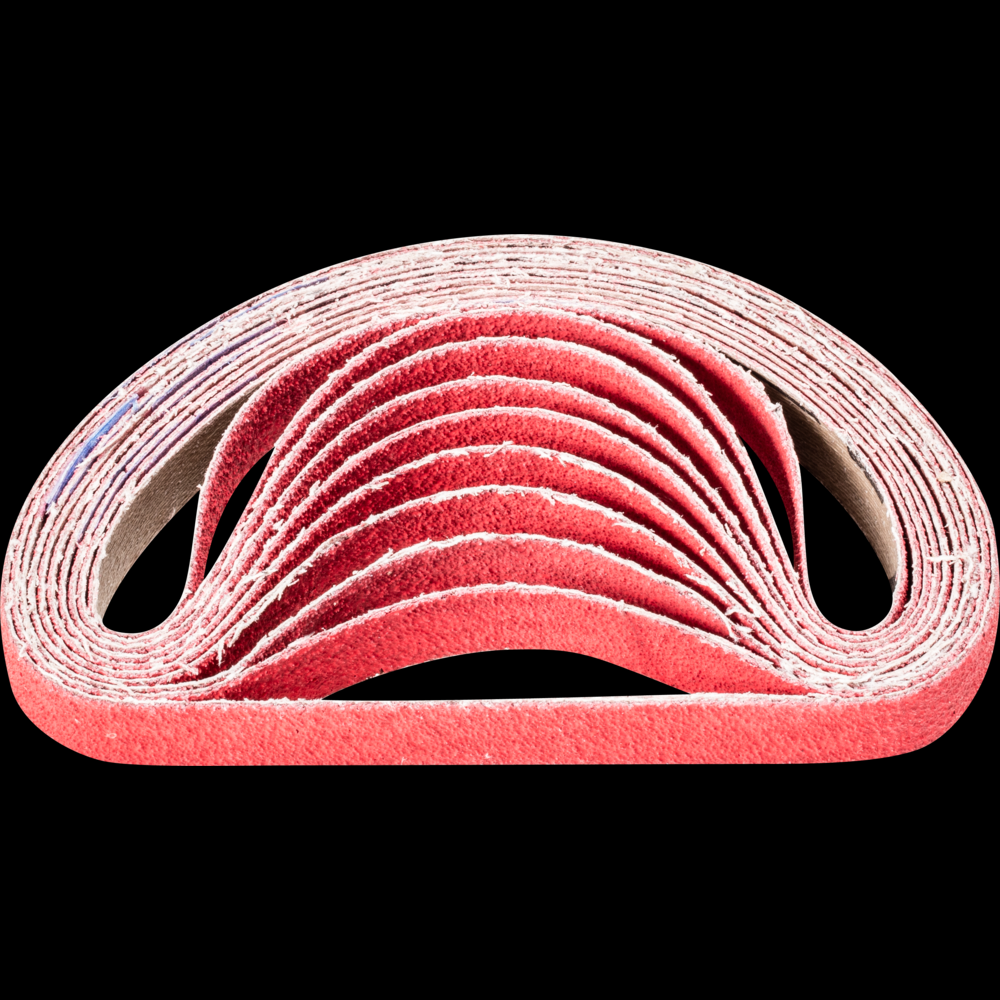

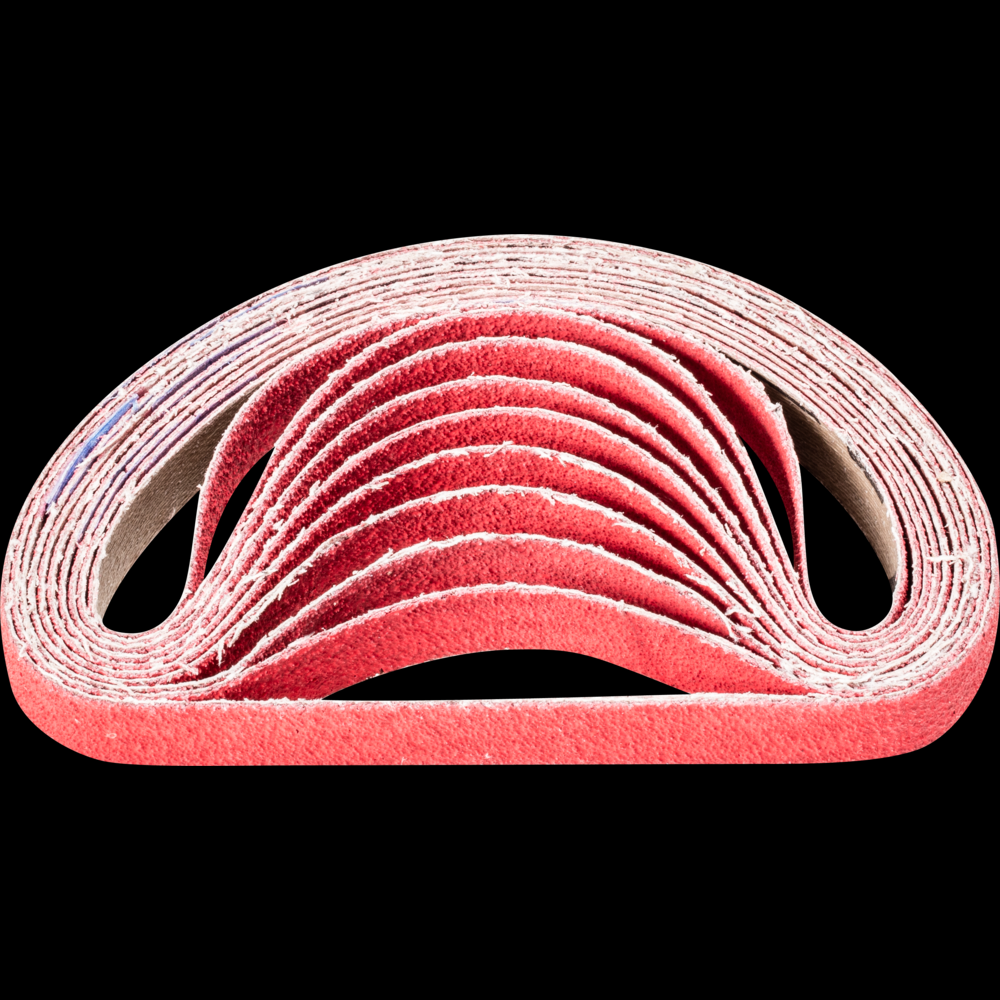

PFERD Abrasive File Belt, 12" x 1/2, 80 Grit, Ceramic CO-COOL by Pferd Inc.

- Part Number: 47501592

- UPC:

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

For aggressive grinding with maximum stock removal rate on hard materials that do not conduct heat well. Consistently high performance due to self-sharpening ceramic oxide grain. Active grinding additives in the coating substantially improve the stock removal rate, prevent loading, and result in cooler grinding. Short belts are compatible with commonly available belt grinders.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Pads, Sponges, Paper and Belts

Industrial Subtype:

Sanding Belts and Kits

Category Level 4:

Sanding Belts

Abrasive:

CO-COOL

Applications:

Deburring

Applications 1:

Step-by-step fine grinding

Applications 2:

Leveling

Applications 3:

Sharpening

Applications 4:

Work on weld seams

Applications 5:

Working on edges

Country of Origin:

DE

Drive Types:

Belt grinder

EDP:

49532

Grit Size:

80

Item Length (inches):

12.00

Item Quantity:

50

Item Weight (kgs):

0.007

MANUFACTURER_TYPE_DESCR:

BA 12/305 X CO-COOL 80

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Annealed cast iron

Materials that can be worked 2:

Bronze

Materials that can be worked 3:

Cobalt-based alloys

Materials that can be worked 4:

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Materials that can be worked 5:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Materials that can be worked 6:

Stainless steel (INOX)

Materials that can be worked 7:

Titanium

Order Quanityt:

190

Prop 65:

View

Recommendations for use:

Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

Safety notes:

Follow all safety instructions for abrasive belt use.

UNSPNC:

31191507

UPC Code:

97758495325

Manufactured By:

Pferd Inc.

Other Details

Consistent work results due to high grain adhesion.

Cost-effective due to high abrasive performance and durability.

High tear strength with optimum flexibility.