Return

Print

Email

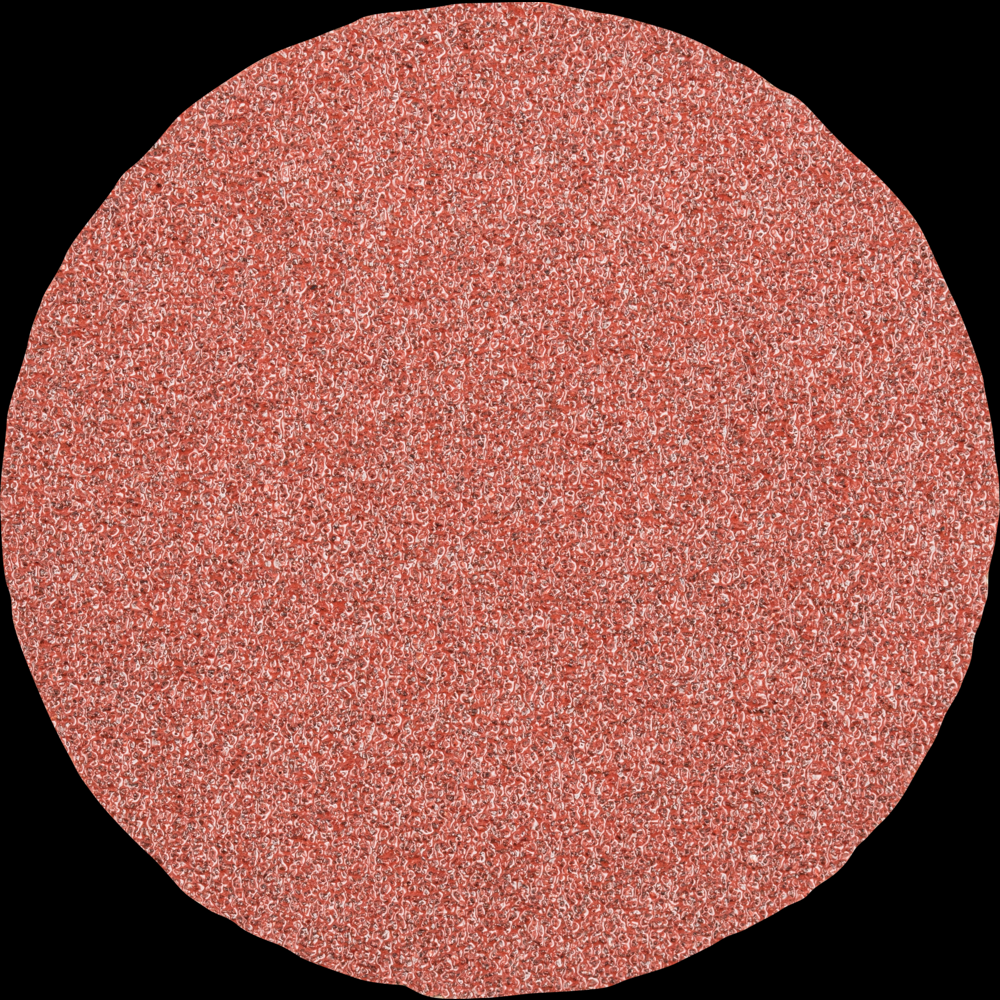

PFERD ALUMASTER High Speed Disc 4-1/2"/5" with HICOAT® Inserts by Pferd Inc.

- Part Number: 22000021

- UPC: 04007220107515

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

The innovative High Speed Disc ALUMASTER is a unique tool with an extremely high stock removal rate. It is ideal for processing aluminum as it does not generate hazardous or explosive dust. The ALUMASTER includes specially developed tungsten carbide cutting inserts fixed to the High Speed Disc. Special disc for processing aluminum alloys using an angle grinder. Version with HICOAT® coating for processing particularly demanding materials. Also suited to peripheral milling and milling out root seams. HSD-R version for radial applications. High Speed Disc ALUMASTER HSD-R 4-1/2"/5" HICOAT® including pre-mounted tungsten carbide cutting inserts, TORX key, and plastic box.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Cut-Off and Grinding Wheels

Category Level 4:

Abrasive Cut-Off and Chop Wheels

Applications:

Milling

Applications 1:

Milling out

Applications 2:

Root seam processing

Applications 3:

Surface work

Applications 4:

Work on weld seams

Applications 5:

Work on fillet welds

Country of Origin:

DE

Customs Number:

8207703030

Cut:

1

Drive Types:

Manual application

EAN:

4007220107515

EDP:

20110

Item Quantity:

1

Item Weight (kgs):

0.506

MANUFACTURER_TYPE_DESCR:

HSD-R 115/125 ALUMASTER HICOAT

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Brass

Materials that can be worked 10:

Soft aluminium alloys

Materials that can be worked 11:

Thermoplastics

Materials that can be worked 12:

Tough aluminium alloys

Materials that can be worked 13:

Zinc

Materials that can be worked 2:

Bronze

Materials that can be worked 3:

Copper

Materials that can be worked 4:

Fibre-reinforced thermosetting plastics (GRP, CRP)

Materials that can be worked 5:

Fibre-reinforced thermosetting plastics (GRP, CRP) with a fibre content ≤ 40 %

Materials that can be worked 6:

Fibre-reinforced thermosetting plastics (GRP, CRP) with a fibre content > 40 %

Materials that can be worked 7:

Hard aluminium alloys

Materials that can be worked 8:

Hard non-ferrous metal

Materials that can be worked 9:

Plastics

Prop 65:

View

Recommendations for use:

The ALUMASTER has been designed primarily for use on aluminum, wrought aluminum alloys, and cast aluminum. It can also machine non-ferrous metals that have a relatively low strength, and it can machine fiber-reinforced plastics. Check this for the specific

Recommendations for use 1:

Do not push the disc deep into a workpiece. The milling disc is not a cutting tool.

Recommendations for use 2:

Do not exert unnecessarily high forces on the angle grinder. The ALUMASTER High Speed Disc already works with low forces.

Recommendations for use 3:

When machining workpiece edges, cut along the edge, never across the edge.

Recommendations for use 4:

Do not decelerate the disc while it is touching the workpiece. The cutting inserts may break.

Recommendations for use 5:

HICOAT® coating allows for use on very complex materials like cast aluminum alloys with 5-10% silicon content, sticky and greasy materials, abrasive cast aluminum alloys with a silicon content over 15%, abrasive materials like fibre-reinforced plastics (F

Safety notes:

The flange nut must be tightened with the appropriate tool, such as a face pin wrench. Clamping systems which are designed to be tightened without the use of an additional tool, i.e. which are tightened by hand, should not be used.

Safety notes 1:

Tighten the mounting bolts of the cutting inserts using a torque spanner with a tightening torque of 4 Nm. The part number for the 4 Nm torque spanner is 20135.

Safety notes 2:

Loose cutting inserts may break during use. Regularly check to make sure they are attached securely.

Safety notes 3:

Do not use damaged cutting inserts, they may break.

Shape:

Square

UNSPNC:

27112838

UPC Code:

97758201100

Manufactured By:

Pferd Inc.

Other Details

Cost-effective and eco-friendly alternative to grinding wheels and flap discs of comparable weight.

Does not generate hazardous or explosive aluminum dust.

Does not require an extraction system.

Exceptionally high stock removal rate.

Extremely high degree of hardness, very low friction coefficient, very low tendency towards adhesion, improved surface quality, and reduced burr formation, all due to the HICOAT® coating

Innovative and robust cut geometry for maximum safety, extreme durability, and ease of work.

Specially developed, turnable, and replaceable tungsten carbide cutting inserts.