Return

Print

Email

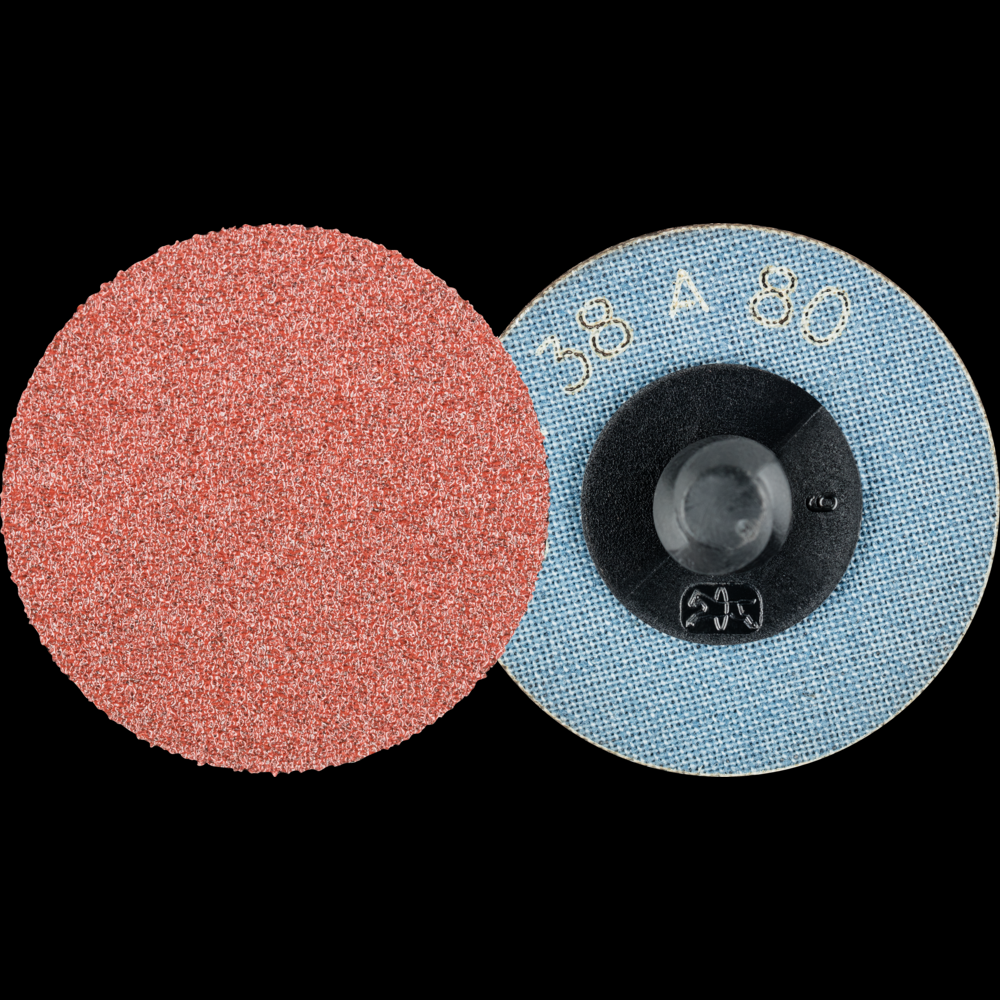

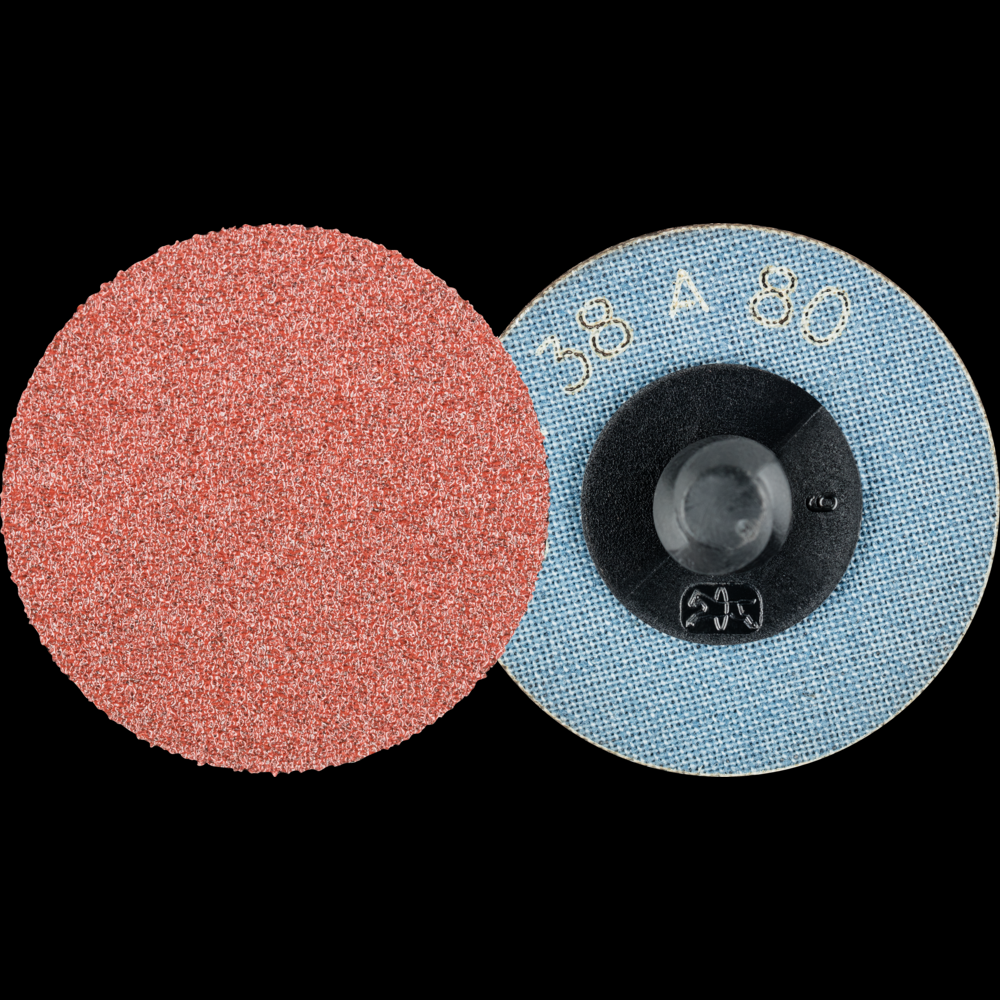

PFERD COMBIDISC® Abrasive Disc, 1-1/2" Dia, Type CDR, 80 Grit, Aluminum oxide by Pferd Inc.

- Part Number: 42770408

- UPC: 04007220596470

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

For universal coarse to fine grinding applications in industry and professional trades. The CDR clamping system has a threaded connection with male thread (plastic). Also compatible with the following commonly used systems: Roloc™, Lockit, Speed Lok TR, Power Lock Type III, Fastlock-System B, Roll-On.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Sanding Discs and Kits

Category Level 4:

Quick Change Discs

Abrasive:

Aluminium oxide A

Applications:

Deburring

Applications 1:

Step-by-step fine grinding

Applications 2:

Leveling

Applications 3:

Roughening

Applications 4:

Sharpening

Applications 5:

Surface work

Applications 6:

Work on weld seams

Applications 7:

Working on edges

Clamping System:

CDR system

Country of Origin:

DE

Customs Number:

6805100000

Diameter External (In):

1.50

Drive Types:

Angle grinder

Drive Types 1:

Cordless angle grinder

Drive Types 2:

Flexible shaft drive

Drive Types 3:

Straight grinder

EAN:

4007220596470

EDP:

42494

Grit Size:

80

Item Quantity:

100

Item Weight (kgs):

0.003

MANUFACTURER_TYPE_DESCR:

CDR 38 A 80

Materials that can be worked:

Annealed cast iron

Materials that can be worked 1:

Brass

Materials that can be worked 10:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 11:

Thermoplastics

Materials that can be worked 12:

Titanium

Materials that can be worked 13:

Titanium alloys

Materials that can be worked 2:

Bronze

Materials that can be worked 3:

Cast steel

Materials that can be worked 4:

Copper

Materials that can be worked 5:

Fibre-reinforced thermosetting plastics (GRP, CRP)

Materials that can be worked 6:

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Materials that can be worked 7:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 8:

Stainless steel (INOX)

Materials that can be worked 9:

Steel materials with a hardness > 54 HRC

Optimum RPM:

10000 - 16000 RPM

Order Quanityt:

90

Pferdefficiency:

PFERDEFFICIENCY recommends COMBIDISC® products to reduce disc change and setup times.

Pferdergonomics:

PFERDERGONOMICS recommends COMBIDISC® as an innovative solution to reduce vibration, noise and dust produced during use and to improve comfort when working.

Prop 65:

View

Recommendations for use:

Use COMBIDISC® grinding discs with arbors or abrasive disc holders on flexible shaft drives with angle handpieces, compressed-air or electric angle grinders.

Recommendations for use 1:

Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

Safety notes:

The maximum permitted peripheral speed is 9,800 SFPM.

Safety notes 1:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

UNSPNC:

31191506

UPC Code:

97758424943

Manufactured By:

Pferd Inc.

Other Details

Convenient to use due to simple handling and low-vibration working.

No operational disruptions caused by sticking, slipping, or disengaging.

Reduced down time due to quick changes.

Add this new item to:

View your added items here.

Point of Sale