Return

Print

Email

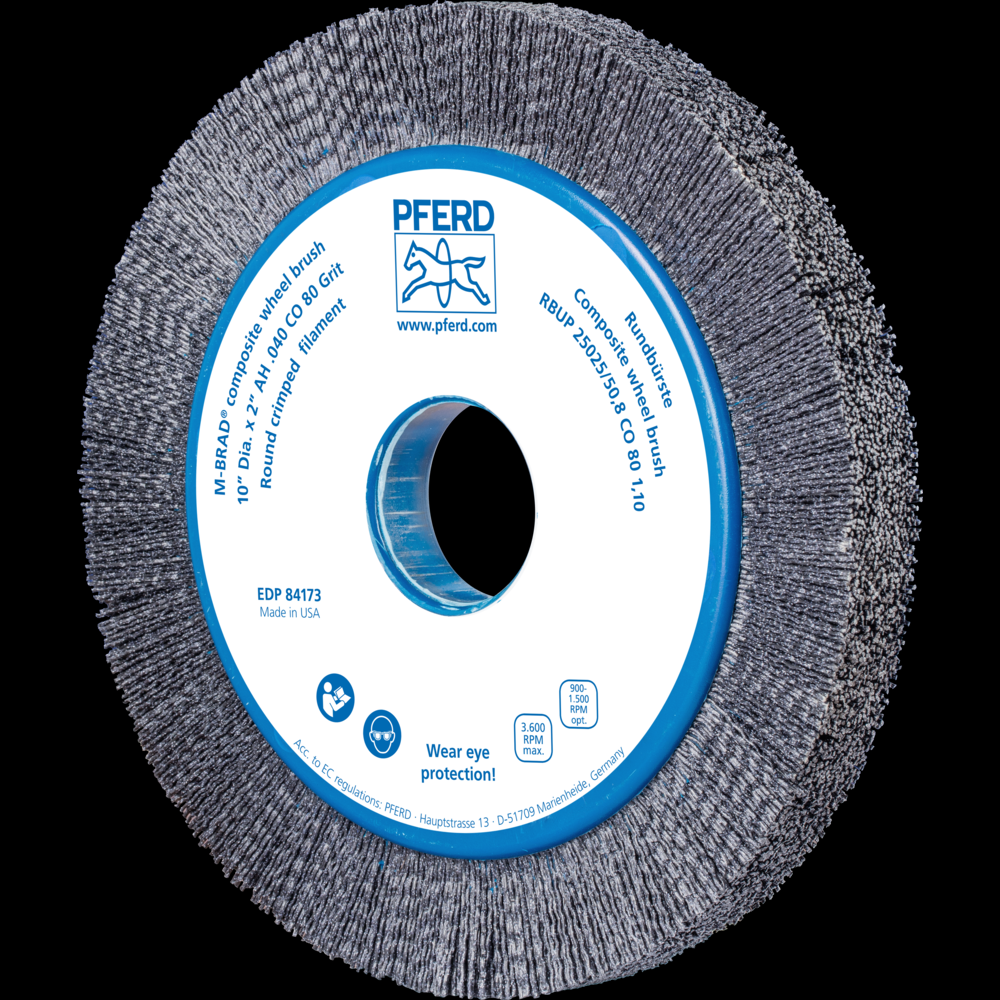

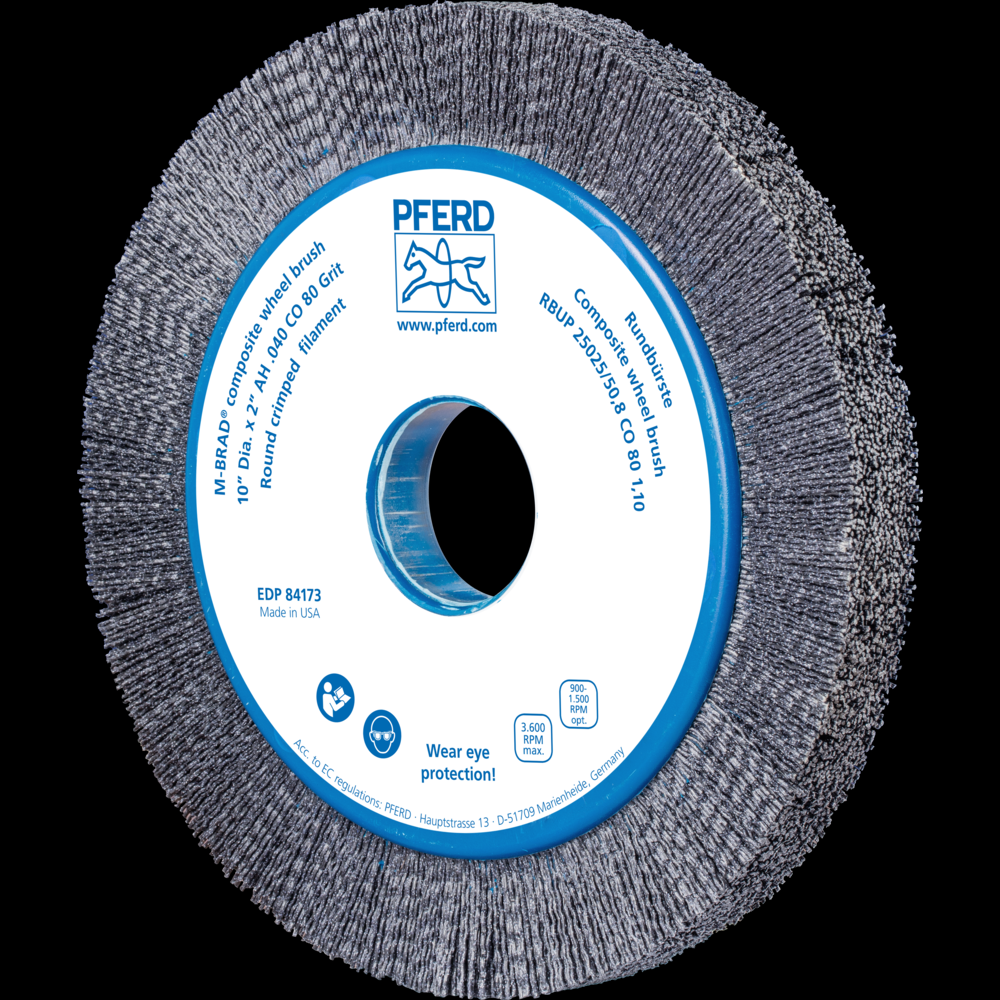

PFERD M-BRAD® Composite Wheel Brush 10" Dia. .040/80 Grit Ceramic Oxide 2" Arbor by Pferd Inc.

- Part Number: 79184173

- UPC: 04007220956724

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

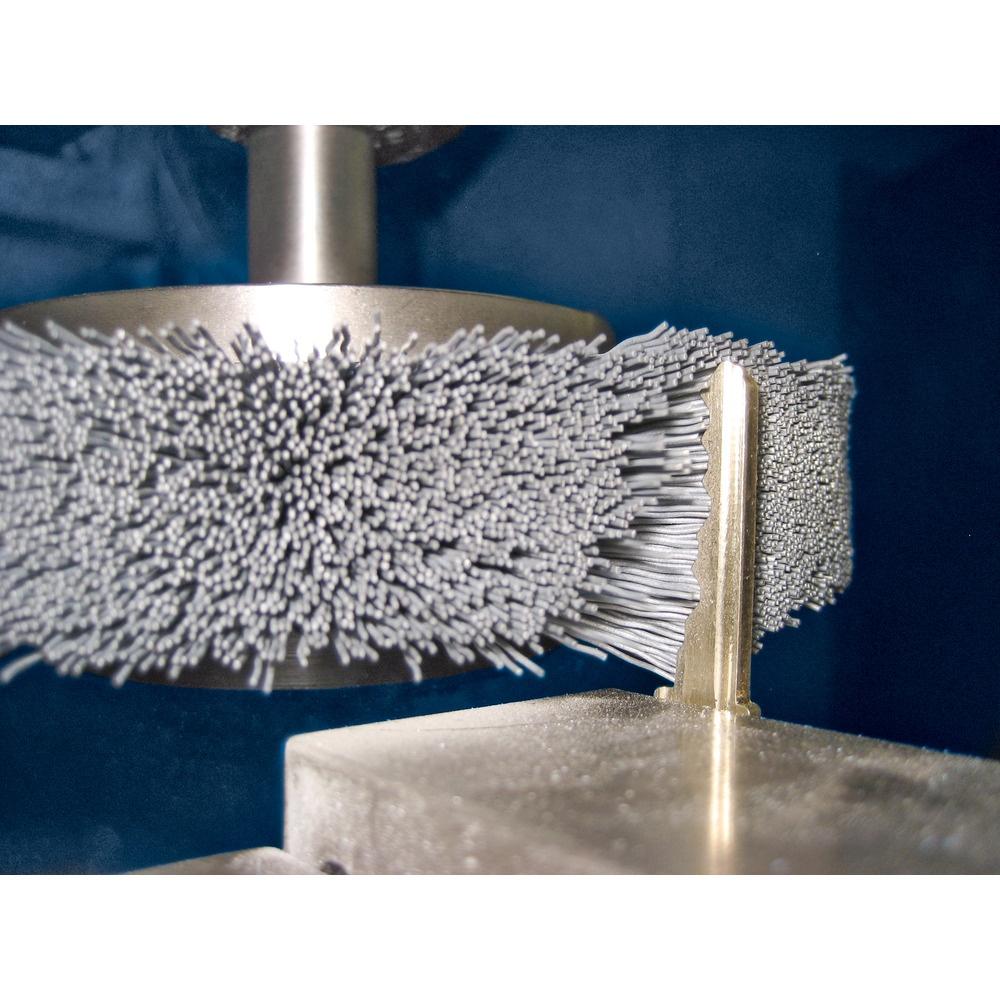

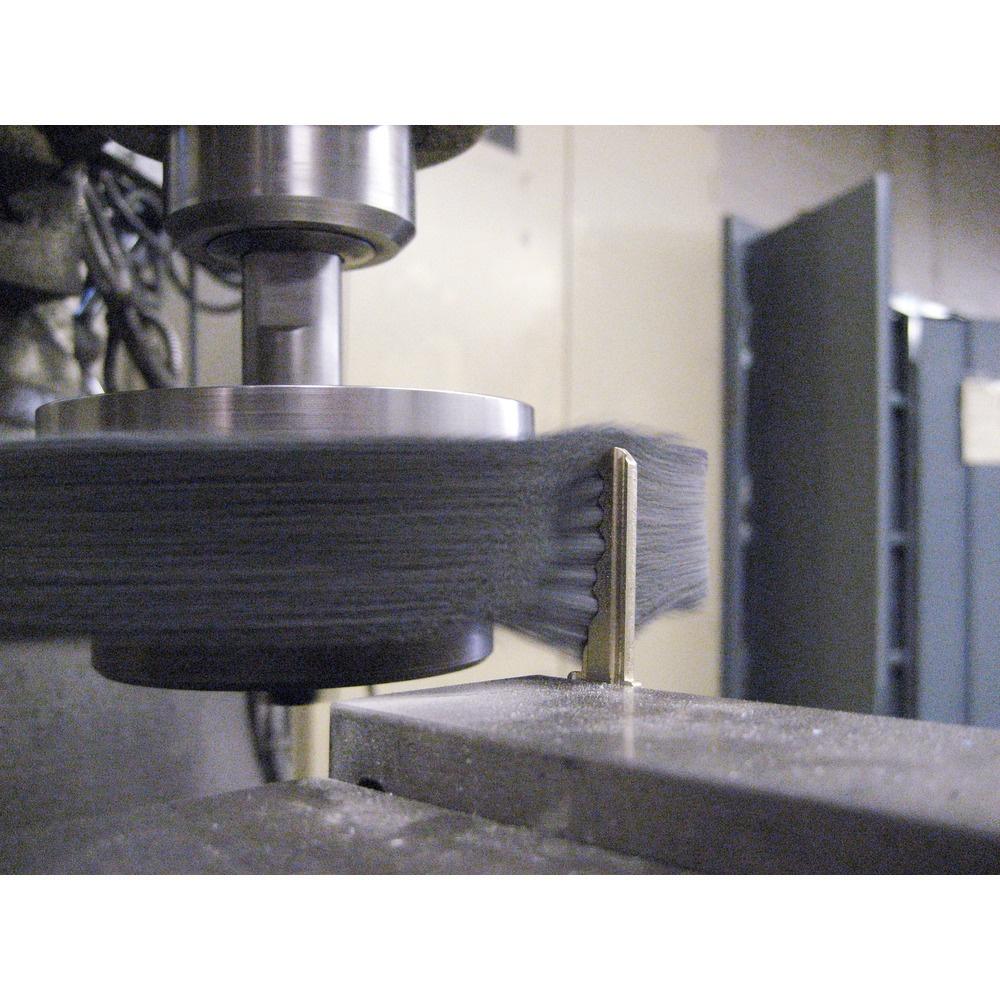

Particularly aggressive brush. Its plastic filament makes this product ideal for deburring complicated components such as cylinder heads or gear toothing, as well as for working on surfaces. Developed specially for industrial use. Composite brushes from PFERD have been specifically developed for industrial, automated use. They are suitable for a variety of applications and their variable mounting options mean that they can be used on many different drive systems. This offers the advantage that the workpiece can be produced and finished on the same machine. As a result, labour-intensive, manual work is reduced and repeatable results are achieved with short cycle times. Brushes with ceramic oxide grain (CO) offer good toughness and excellent sharpness. For high stock removal and aggressive brushing action. Platstic filaments are temperature-resistant up to 410°F.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Abrasive Brushes

Category Level 4:

Wire Wheel Brushes

Applications:

Cleaning

Applications 1:

Deburring

Applications 2:

Structuring (matt finishing, brush matting and satin finishing)

Country of Origin:

US

Diameter Arbor Hole With Adapter:

2 Inch

Diameter External (In):

10.00

Diameter Filament Material (In):

0.04

Diameter Hole:

2 Inch

Drive Types:

Tool machine

Drive Types 1:

Robot

Drive Types 2:

Stationary machines

EAN:

4007220956724

EDP:

84173

Filament Material:

Ceramic oxide grain (CO)

Grit Size:

80

Installation Width (In):

1.00

Item Quantity:

1

Item Weight (kgs):

1.418

MANUFACTURER_TYPE_DESCR:

RBUP 25025/50,8 CO 80 1,10

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Bronze

Materials that can be worked 10:

Soft titanium alloys (tensile strength 500 N/mm²)

Materials that can be worked 11:

Steel, cast steel

Materials that can be worked 12:

Steel materials with a hardness > 54 HRC

Materials that can be worked 13:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 14:

Titanium

Materials that can be worked 15:

Titanium alloys

Materials that can be worked 2:

Cast iron

Materials that can be worked 3:

Cast steel

Materials that can be worked 4:

Cobalt-based alloys

Materials that can be worked 5:

Hard non-ferrous metal

Materials that can be worked 6:

High-temperature-resistant materials

Materials that can be worked 7:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Materials that can be worked 8:

Nickel or titanium-based superalloys

Materials that can be worked 9:

Other non-ferrous metals

Mounting System:

Centre hole

Optimum RPM:

500 - 800 RPM

Order Quanityt:

50

Pferdefficiency:

PFERDEFFICIENCY recommends composite brushes to achieve maximum stock removal as quickly as possible.

Pferdergonomics:

PFERDERGONOMICS recommends composite brushes to sustainably reduce the vibrations produced during use.

Prop 65:

View

Recommendations for use:

Please observe the recommended rotational speeds.

Recommendations for use 1:

The CO filament material is designed for particularly aggressive machining and for achieving a high surface quality.

Recommendations for use 2:

Use coolant for applications where large amounts of heat are produced.

Trim Length (In):

1.50

UNSPNC:

31191521

Manufactured By:

Pferd Inc.

Other Details

Abrasive grains are embedded in flexible plastic filaments, which means that the filament works on the sides as well as at the tip.

Extremely smooth operation due to evenly distributed filament material.

For particularly aggressive machining and for creating a high surface quality.

Long tool life and aggressive brushing action due to a very high filament density.