Return

Print

Email

PFERD Miniature Cup Brush 9/16" Dia. .005 by Pferd Inc.

- Part Number: 79183250

- UPC: 04007220046586

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

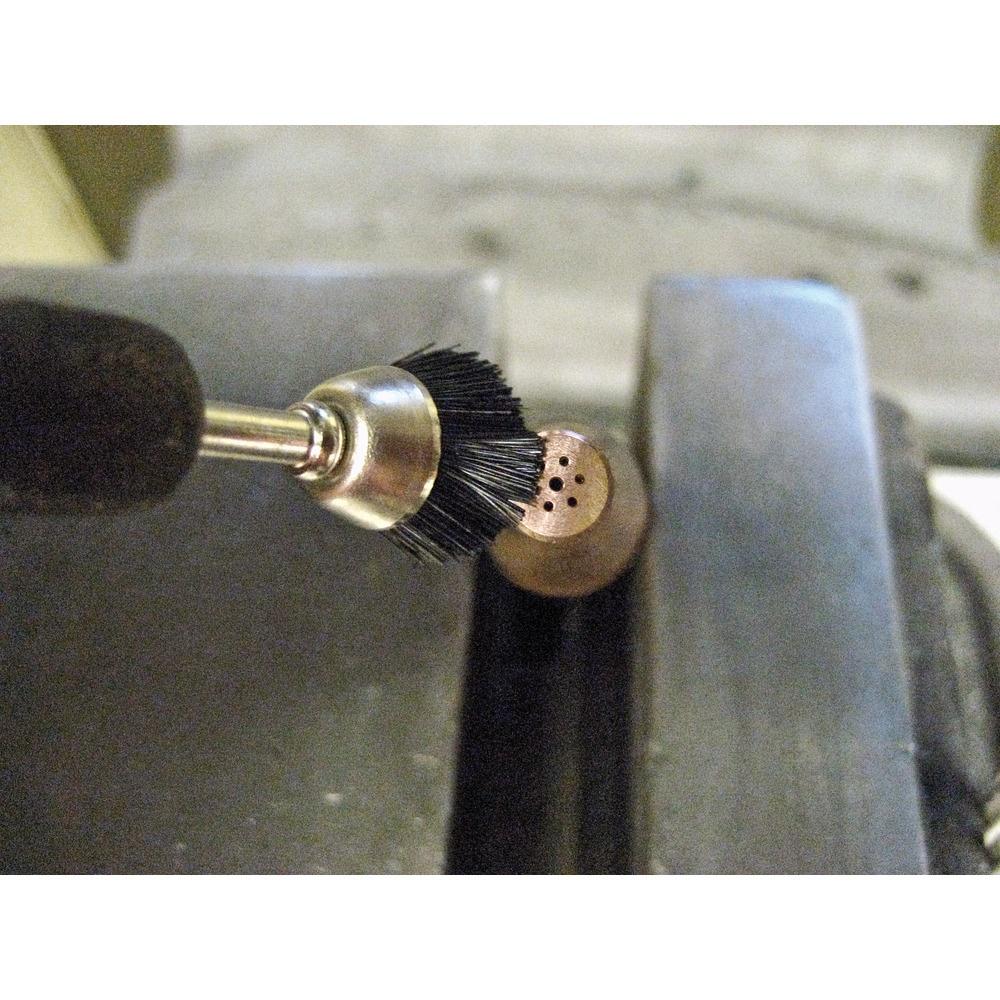

Designed for light brushing such as deburring, cleaning and polishing. Ideal for brushing on small surfaces due to face-down use with the entire brush face applied to the workpiece. PFERD offers a wide range of miniature brushes for precision work. These can be used on flexible shaft drives, micro motors or electric grinders. Brushes with natural bristles (animal hair) are designed for light cleaning and dust removal, as well as for polishing (in combination with polishing pastes). These bristles are harder and less flexible than other natural bristle types. Natural bristles are temperature-resistant up to 300°F.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Abrasive Brushes

Category Level 4:

Cup Brushes

Applications:

Cleaning

Applications 1:

Polishing

Country of Origin:

US

Customs Number:

9603500000

Diameter External (In):

0.56

Diameter Shank:

1/8 Inch

Drive Types:

Flexible shaft drive

Drive Types 1:

Straight grinder

EAN:

4007220046586

EDP:

83250

Filament Material:

Bristle, black

Item Quantity:

36

Item Weight (kgs):

0.007

MANUFACTURER_TYPE_DESCR:

TBU 1803/3,18 SBS

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Brass

Materials that can be worked 10:

Nickel or titanium-based superalloys

Materials that can be worked 11:

Other non-ferrous metals

Materials that can be worked 12:

Soft titanium alloys (tensile strength 500 N/mm²)

Materials that can be worked 13:

Stainless steel (INOX)

Materials that can be worked 14:

Steel, cast steel

Materials that can be worked 15:

Steel materials with a hardness > 54 HRC

Materials that can be worked 16:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 17:

Titanium

Materials that can be worked 18:

Titanium alloys

Materials that can be worked 19:

Zinc

Materials that can be worked 2:

Bronze

Materials that can be worked 3:

Cast iron

Materials that can be worked 4:

Cast steel

Materials that can be worked 5:

Cobalt-based alloys

Materials that can be worked 6:

Copper

Materials that can be worked 7:

Hard non-ferrous metal

Materials that can be worked 8:

High-temperature-resistant materials

Materials that can be worked 9:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Mounting System:

Shank

Optimum RPM:

5000 - 10000 RPM

Order Quanityt:

10

Prop 65:

View

Recommendations for use:

Please observe the recommended rotational speeds.

Recommendations for use 1:

Use brush with polishing paste to achieve the best polishing result.

Safety notes:

When clamping the brush, ensure that the shank is clamped as far into the arbor as possible. This especially applies to high rotational speed ranges. The minimum clamping length is 10 mm.

Trim Length (In):

0.25

UNSPNC:

27111907

Manufactured By:

Pferd Inc.

Other Details

Highly flexible, enabling optimal adaptation to the workpiece contour.

Maximum precision and efficiency on delicate workpieces.