Return

Print

Email

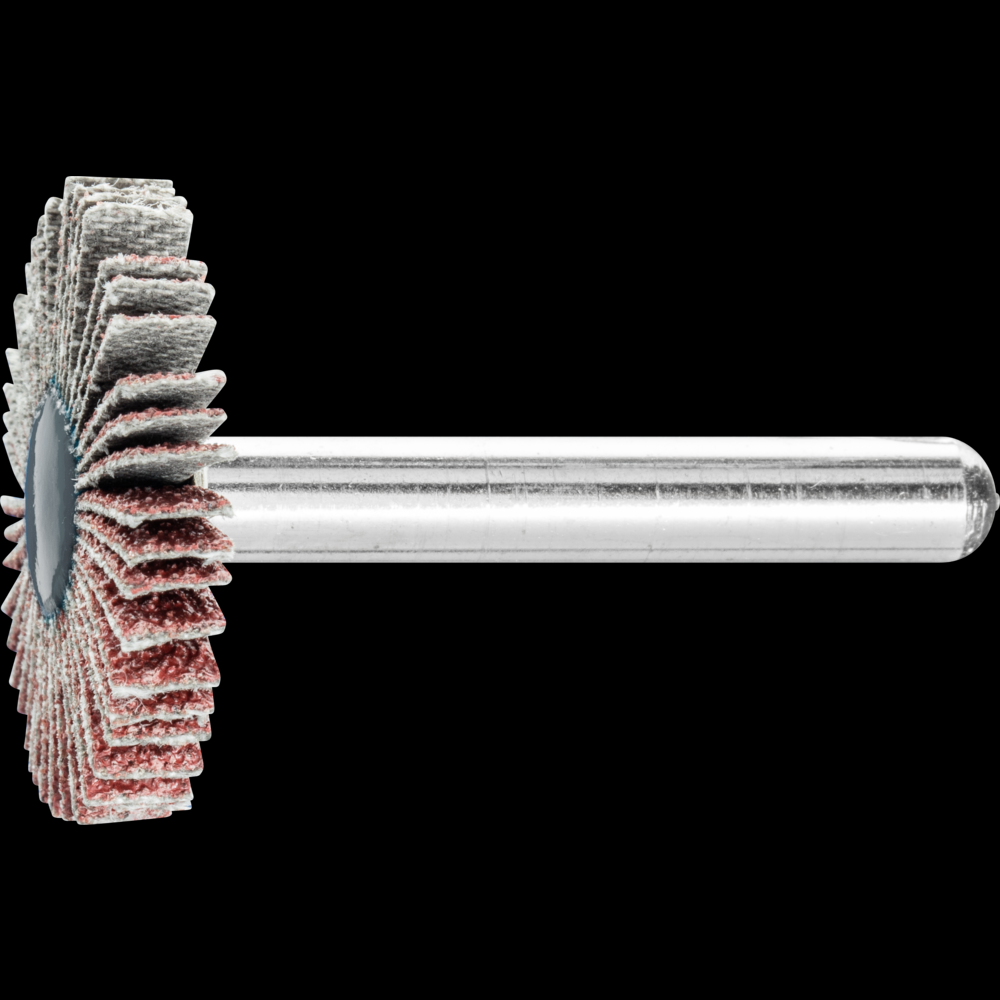

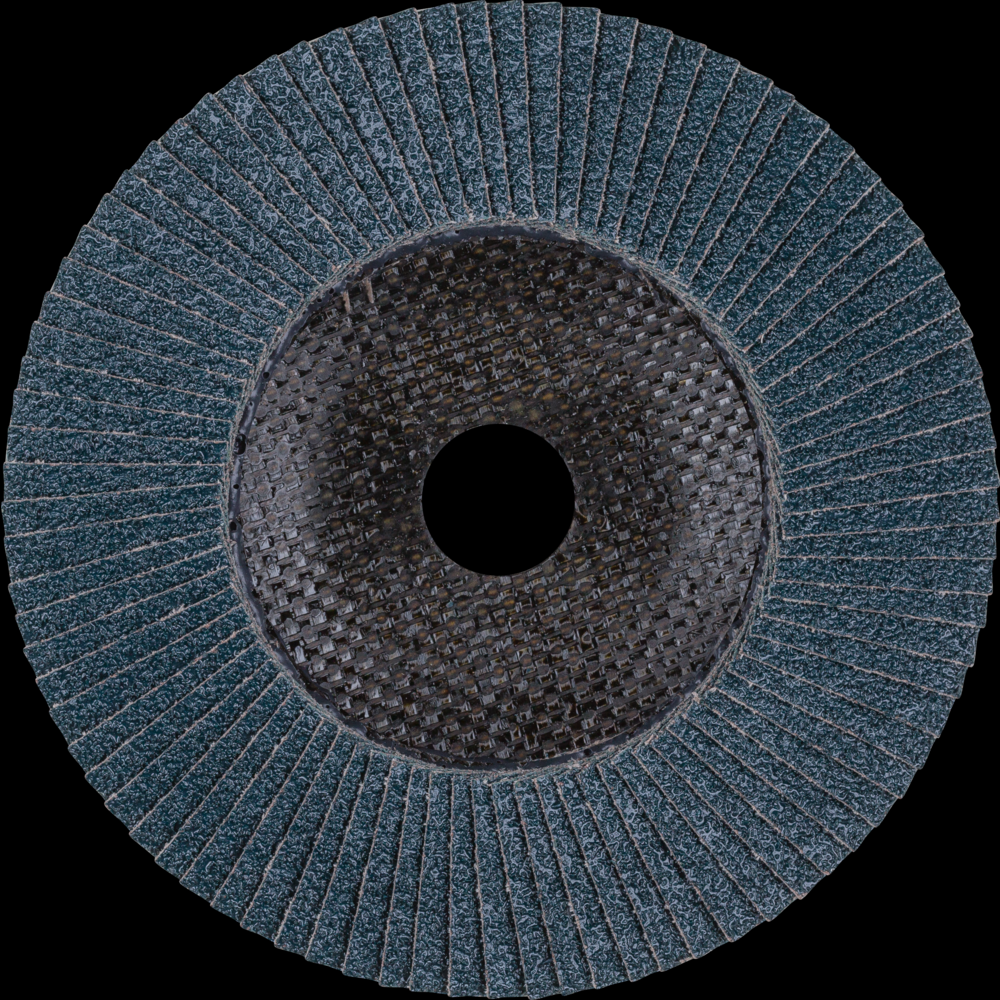

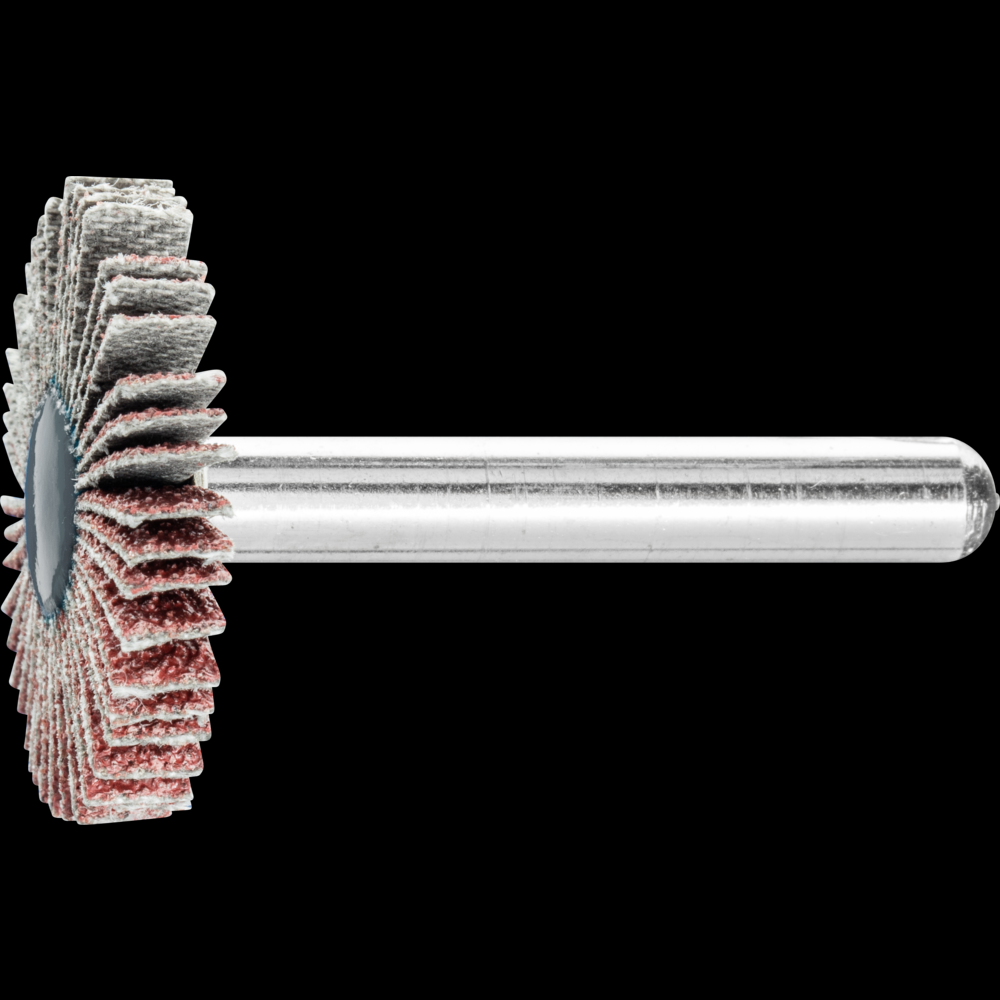

PFERD Mounted Flap Wheel, 1-3/16" x 1/4, 60 Grit, 1/4" Shank, Aluminum oxide by Pferd Inc.

- Part Number: 47801275

- UPC: 04007220338063

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

With mounted flap wheels, coated abrasive flaps are arranged radially around the core in a fan-like structure. The flexible flaps perfectly adapt to surface contours. The abrasive grain is embedded in the sturdy, flexible cloth backing material with a resinoid bond. In ISO 3919, mounted flap wheels are designated as "flap wheels with shaft." For universal applications from coarse to fine grinding.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Flap Wheels

Category Level 4:

Mounted Flap Wheels

Abrasive:

Aluminium oxide A

Applications:

Deburring

Applications 1:

Step-by-step fine grinding

Applications 2:

Leveling

Applications 3:

Structuring (matt finishing, brush matting and satin finishing)

Applications 4:

Surface work

Applications 5:

Work on weld seams

Country of Origin:

ES

Diameter External (In):

1.17

Diameter Shank:

1/4 Inch

Drive Types:

Flexible shaft drive

Drive Types 1:

Straight grinder

EAN:

4007220338063

EDP:

45007

Grit Size:

60

Item Quantity:

10

Item Weight (kgs):

0.014

MANUFACTURER_TYPE_DESCR:

F 3005 6,35 A 60

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Annealed cast iron

Materials that can be worked 2:

Brass

Materials that can be worked 3:

Cast steel

Materials that can be worked 4:

Copper

Materials that can be worked 5:

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Materials that can be worked 6:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 7:

Stainless steel (INOX)

Materials that can be worked 8:

Steel materials with a hardness > 54 HRC

Materials that can be worked 9:

Steels up to 370 HV (< 38 HRC)

Order Quanityt:

150

Pferdergonomics:

PFERDERGONOMICS recommends mounted flap wheels to reduce vibration and noise produced during use and to improve comfort when working.

Prop 65:

View

Recommendations for use:

Flap wheel wear and the thermal load on the workpiece are reduced by decreasing the contact pressure and peripheral speed, and by adding grinding oil.

Recommendations for use 1:

Stock removal rate should be increased by using a coarser grit, not by increasing the contact pressure. This avoids unnecessary flap wheel wear and prevents the thermal load of the workpiece.

Recommendations for use 2:

Increasing the speed results in a slightly finer surface quality. An increase in contact pressure results in a slightly coarser surface. The softer the workpiece material, the coarser the resulting surface (when using the same grit size).

Recommendations for use 3:

For the best performance, use with a recommended peripheral speed of 3,000-4,000 SFPM. This provides an ideal compromise between stock removal rate, surface quality, thermal load on the workpiece and tool wear.

Recommendations for use 4:

Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

Safety notes:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

Safety notes 1:

The contact pressure has to be reduced significantly when the optimum rotational speed is exceeded.

Safety notes 2:

Ensure the clamping depth is at least 5/8" and the specified maximum rotational speed is not exceeded with unsupported shank lengths.

Shank Length:

1.50

UNSPNC:

31191600

UPC Code:

97758450072

Manufactured By:

Pferd Inc.

Other Details

Can be used face-down very close to edges and in corners thanks to the flat, moulded-core design.

Conforms to contours due to high flexibility.

Consistently high stock removal rate throughout the entire service life as new, aggressive abrasive is constantly exposed.