Return

Print

Email

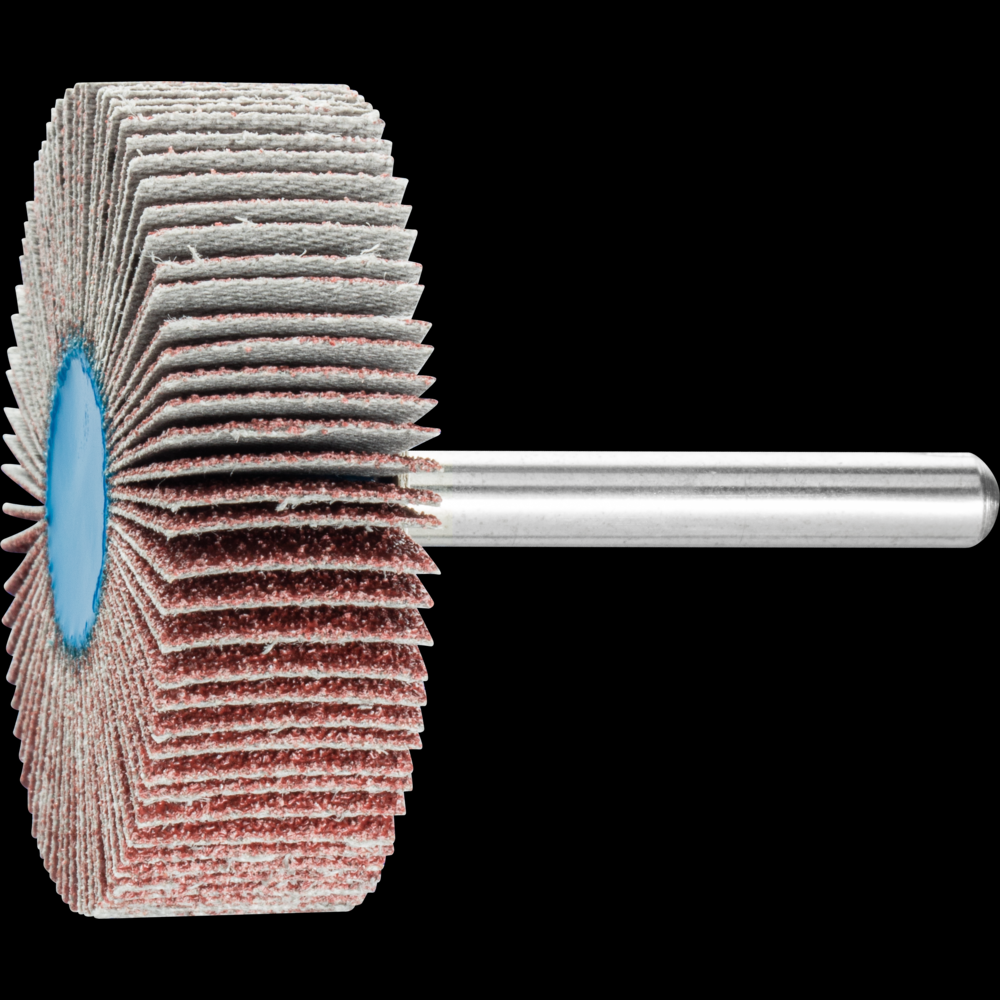

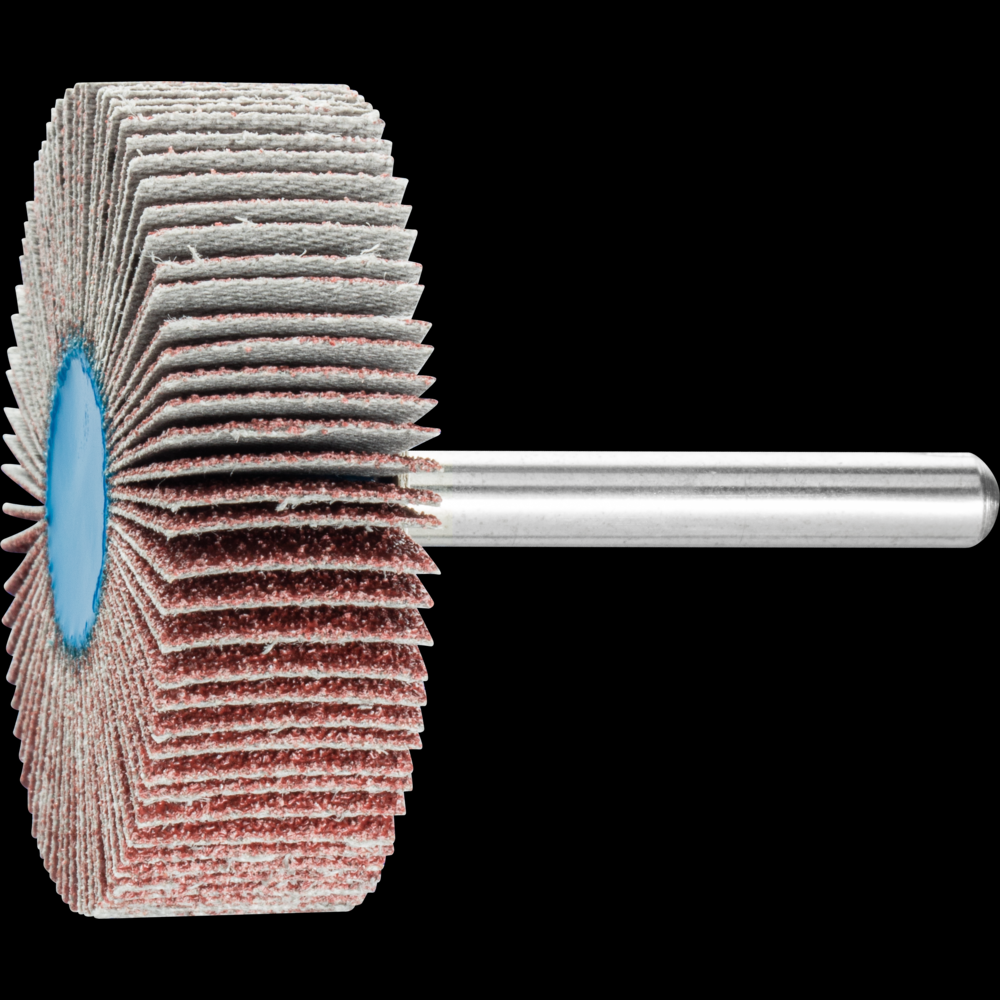

PFERD Mounted Flap Wheel, 2" x 1/2, 80 Grit, 1/4" Shank, Silicon carbide by Pferd Inc.

- Part Number: 47800178

- UPC: 04007220134771

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

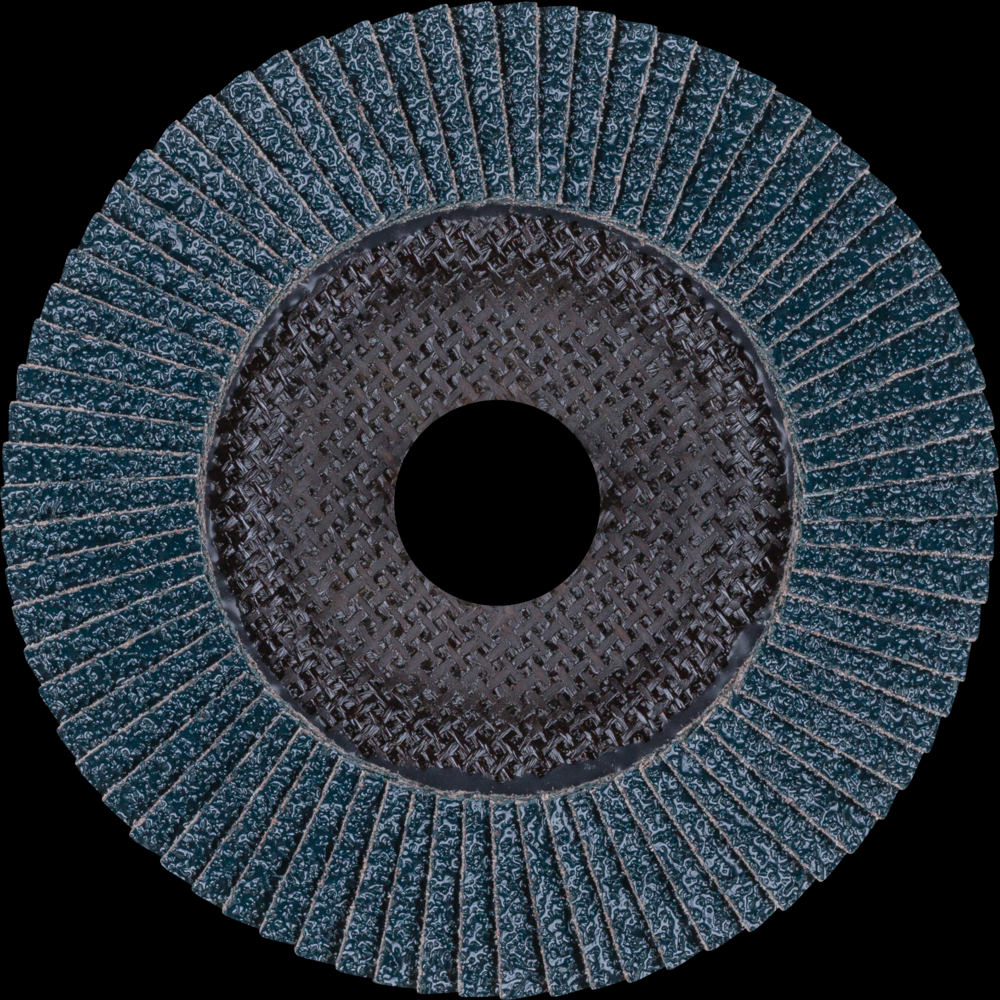

With mounted flap wheels, coated abrasive flaps are arranged radially around the core in a fan-like structure. The flexible flaps perfectly adapt to surface contours. The abrasive grain is embedded in the sturdy, flexible cloth backing material with a resinoid bond. In ISO 3919, mounted flap wheels are designated as "flap wheels with shaft." For universal grinding work on components made from aluminium, copper, bronze, titanium and fibre-reinforced plastics. Excellent for use on titanium alloys. Ideal for the aeronautical industry, especially where SiC is the only approved abrasive, e.g. for use on engine components.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Abrasive Wheels, Discs and Brushes

Industrial Subtype:

Flap Wheels

Category Level 4:

Mounted Flap Wheels

Abrasive:

Silicon carbide SiC

Applications:

Deburring

Applications 1:

Step-by-step fine grinding

Applications 2:

Leveling

Applications 3:

Structuring (matt finishing, brush matting and satin finishing)

Applications 4:

Surface work

Applications 5:

Work on weld seams

Country of Origin:

DE

Diameter External (In):

2.00

Diameter Shank:

1/4 Inch

Drive Types:

Flexible shaft drive

Drive Types 1:

Straight grinder

EAN:

4007220134771

EDP:

45427

Grit Size:

80

Item Quantity:

10

Item Weight (kgs):

0.098

MANUFACTURER_TYPE_DESCR:

F 5113/6,35 SIC 80

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Bronze

Materials that can be worked 2:

Fibre-reinforced thermosetting plastics (GRP, CRP)

Materials that can be worked 3:

Stainless steel (INOX)

Materials that can be worked 4:

Stone

Materials that can be worked 5:

Thermoplastics

Materials that can be worked 6:

Titanium

Materials that can be worked 7:

Titanium alloys

Order Quanityt:

80

Pferdergonomics:

PFERDERGONOMICS recommends mounted flap wheels to reduce vibration and noise produced during use and to improve comfort when working.

Prop 65:

View

Recommendations for use:

Flap wheel wear and the thermal load on the workpiece are reduced by decreasing the contact pressure and peripheral speed, and by adding grinding oil.

Recommendations for use 1:

Stock removal rate should be increased by using a coarser grit, not by increasing the contact pressure. This avoids unnecessary flap wheel wear and prevents the thermal load of the workpiece.

Recommendations for use 2:

Increasing the speed results in a slightly finer surface quality. An increase in contact pressure results in a slightly coarser surface. The softer the workpiece material, the coarser the resulting surface (when using the same grit size).

Recommendations for use 3:

For the best performance, use with a recommended peripheral speed of 3,000-4,000 SFPM. This provides an ideal compromise between stock removal rate, surface quality, thermal load on the workpiece and tool wear.

Recommendations for use 4:

Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

Safety notes:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

Safety notes 1:

The contact pressure has to be reduced significantly when the optimum rotational speed is exceeded.

Safety notes 2:

Ensure the clamping depth is at least 5/8" and the specified maximum rotational speed is not exceeded with unsupported shank lengths.

Shank Length:

1.50

UNSPNC:

31191600

UPC Code:

97758454278

Manufactured By:

Pferd Inc.

Other Details

Can be used face-down very close to edges and in corners thanks to the flat, moulded-core design.

Conforms to contours due to high flexibility.

Consistently high stock removal rate throughout the entire service life as new, aggressive abrasive is constantly exposed.