Return

Print

Email

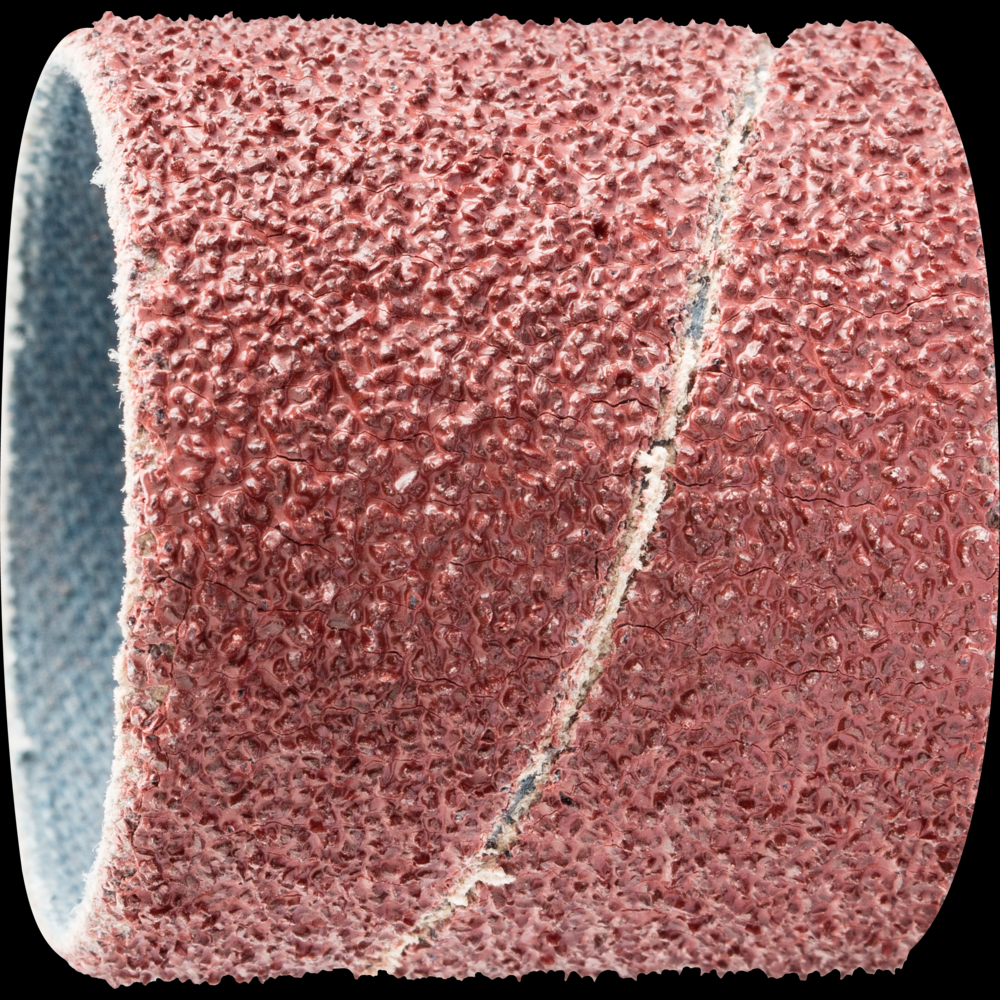

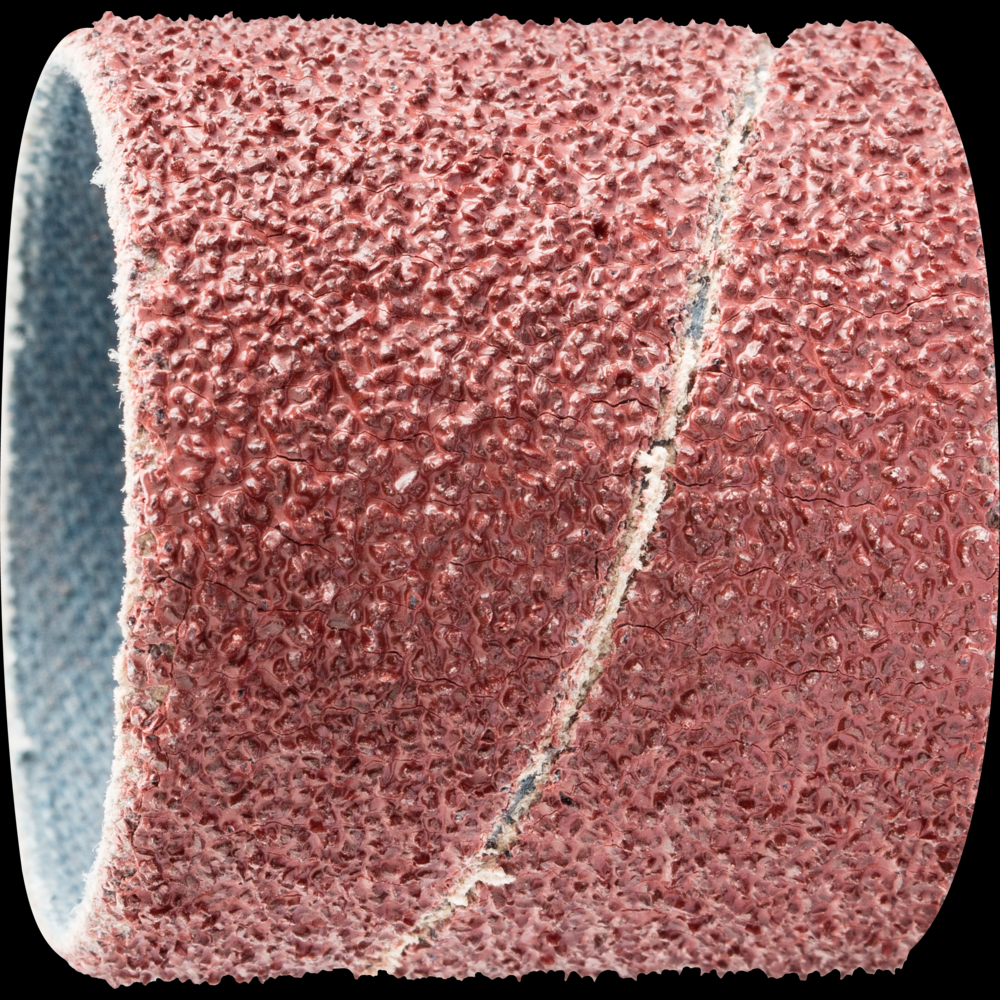

PFERD Spiral Band, 1-1/8" x 1-1/8, Cylindrical Shape, 40 Grit, Aluminum oxide by Pferd Inc.

- Part Number: 42209104

- UPC: 04007220148174

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

For universal applications from coarse to fine grinding. In ISO 2421, abrasive spiral bands are designated as "cylindrical sleeves". GSB = bulk pack of abrasive spiral bands

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Polishing, Finishing and Conditioning

Industrial Subtype:

Spiral Bands

Abrasive:

Aluminium oxide A

Applications:

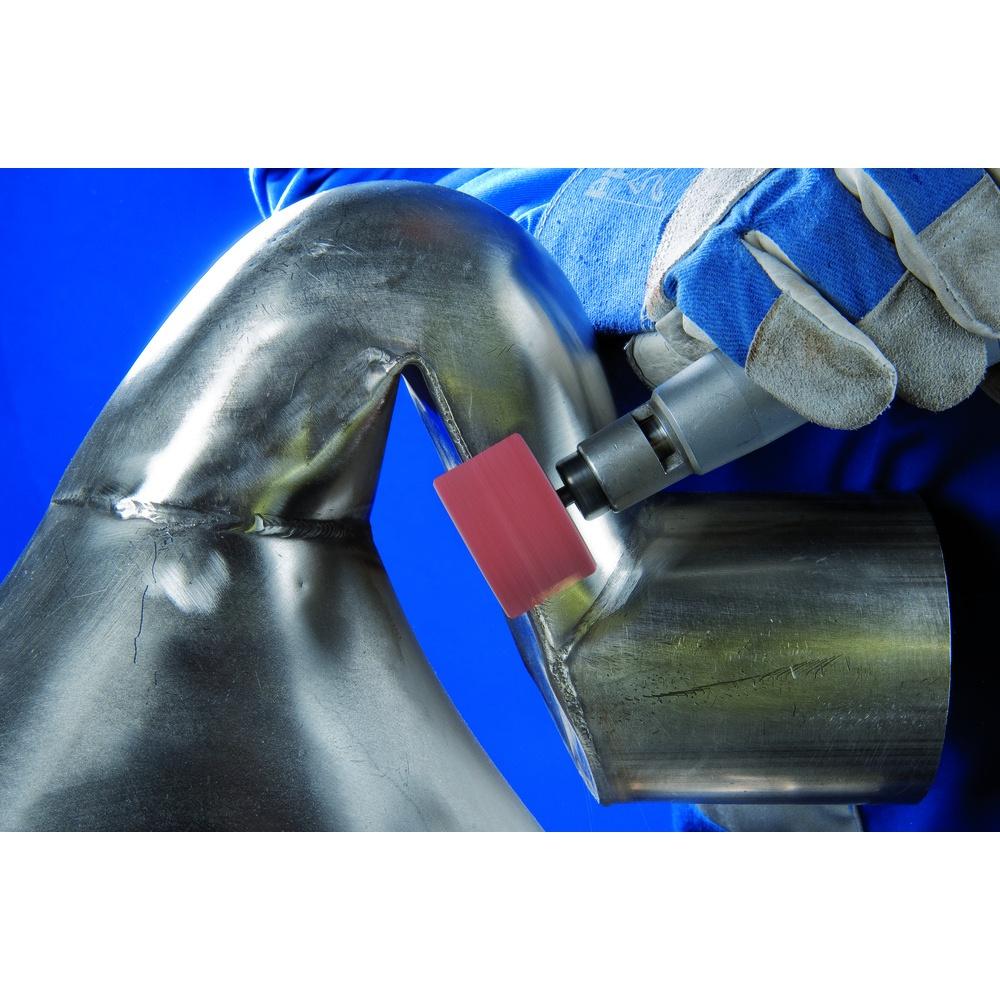

Deburring

Applications 1:

Step-by-step fine grinding

Applications 2:

Leveling

Applications 3:

Roughening

Applications 4:

Sharpening

Applications 5:

Surface work

Applications 6:

Work on weld seams

Applications 7:

Working on edges

Country of Origin:

DE

Diameter External (In):

1.17

Drive Types:

Flexible shaft drive

Drive Types 1:

Straight grinder

EAN:

4007220148174

EDP:

41190

Grit Size:

40

Item Quantity:

100

Item Weight (kgs):

0.007

MANUFACTURER_TYPE_DESCR:

GSB 3030 A 40

Materials that can be worked:

Aluminum

Materials that can be worked 1:

Annealed cast iron

Materials that can be worked 10:

Stainless steel (INOX)

Materials that can be worked 11:

Steel materials with a hardness > 54 HRC

Materials that can be worked 12:

Steels up to 370 HV (< 38 HRC)

Materials that can be worked 13:

Thermoplastics

Materials that can be worked 2:

Brass

Materials that can be worked 3:

Bronze

Materials that can be worked 4:

Cast steel

Materials that can be worked 5:

Cobalt-based alloys

Materials that can be worked 6:

Copper

Materials that can be worked 7:

Fibre-reinforced thermosetting plastics (GRP, CRP)

Materials that can be worked 8:

Grey/nodular cast iron (GG/GJL, GGG/GJS)

Materials that can be worked 9:

Hardened, heat-treated steels over 370 HV (38 HRC)

Optimum RPM:

13000 - 19100 RPM

Order Quanityt:

100

Prop 65:

View

Recommendations for use:

To easily change the abrasive spiral bands, give them a slight clockwise twist and pull them up and off. When doing so, leave the rubber drum holder clamped in the power tool.

Recommendations for use 1:

To ensure the abrasive spiral band is securely attached, follow the minimum speed for the rubber drum holder.

Recommendations for use 2:

For the best performance, use with a recommended peripheral speed of 4,000-6,000 SFPM.

Recommendations for use 3:

Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

Safety notes:

The maximum permitted peripheral speed is 6,000 SFPM.

Safety notes 1:

For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

Safety notes 2:

Do not allow abrasive spiral bands to protrude beyond the rubber drum holder.

UNSPNC:

23131508

UPC Code:

97758411905

Manufactured By:

Pferd Inc.

Other Details

Abrasive spiral bands fit securely on the rubber drum holder as the holder expands during use.

Highest possible cost-effectiveness due to particularly high stock removal rate and aggressiveness of the abrasive.

Outstanding service life even under the toughest work conditions, due to special manufacturing.

Add this new item to:

View your added items here.

Point of Sale