Return

Print

Email

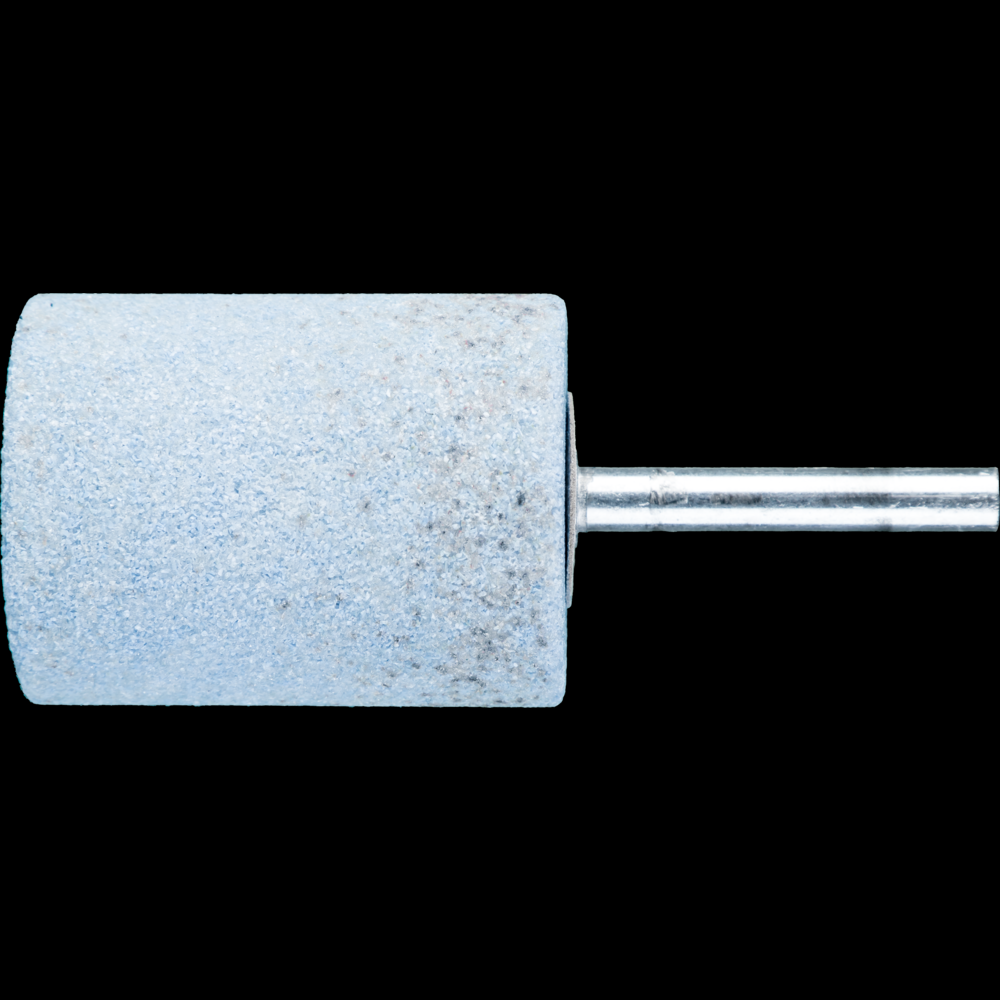

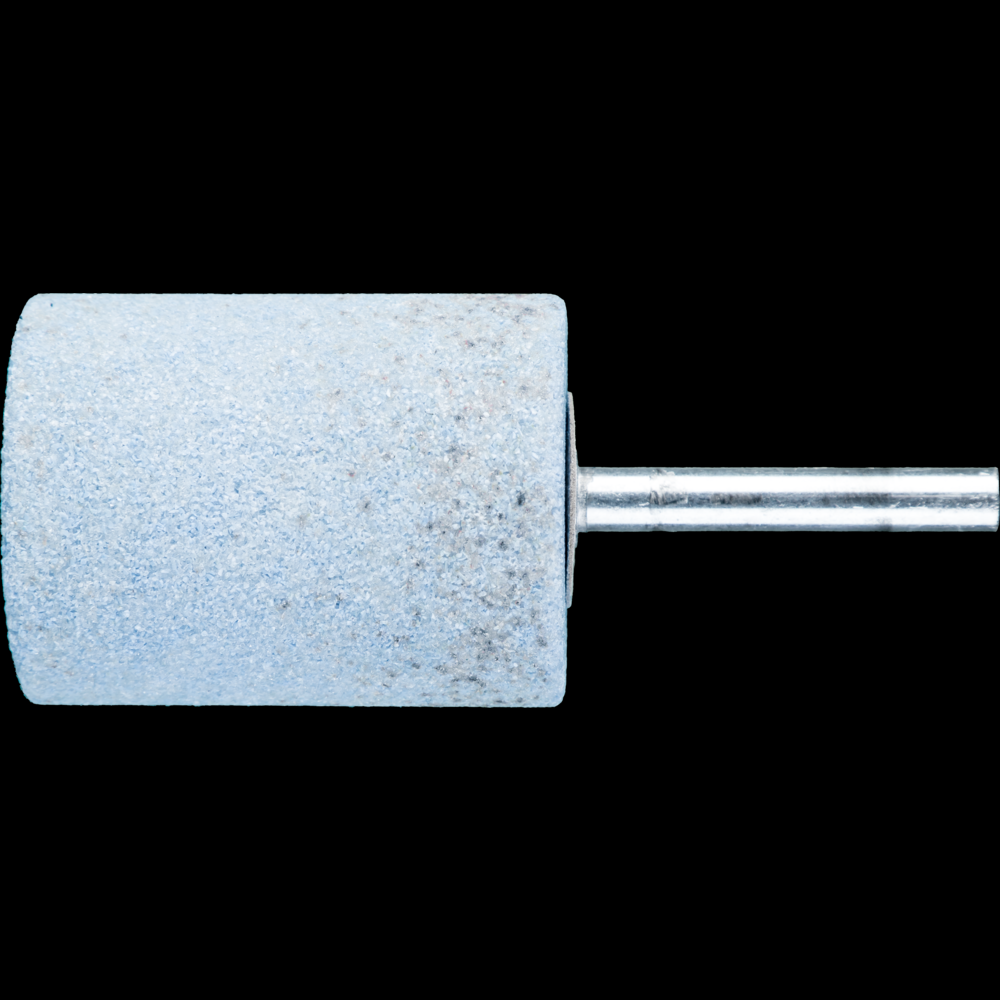

PFERD Vitrified Mounted Point, TOUGH,1-1/2" x 2, 46 Grit, W239,Ceramic Oxide,1/4"Shank by Pferd Inc.

- Part Number: 35492281

- UPC: 04007220847367

- Availability:

Quantity:

Add To Quote

Add To Estimate

Add To Wishlist

Compare Item

Product Overview

Info & Guides

The TOUGH type is specifically designed for use on titanium materials, nickel-based and cobalt-based alloys, hardened steel components and built-up weld deposits. Its applications include weld dressing on repair welds and reworking on turbine blades during aircraft maintenance and regrinding of repair welds in tool and die-making. The cylindrical shape is ideal for grinding bores, radii and contours.

Specifications

Details

Industrial Category:

Abrasives

Industrial Subcategory:

Polishing, Finishing and Conditioning

Industrial Subtype:

Mounted Points

Applications:

Deburring

Applications 1:

Finishing

Applications 2:

Grinding out

Applications 3:

Grouting

Applications 4:

Leveling

Applications 5:

Surface work

Applications 6:

Work on weld seams

Applications 7:

Working on edges (chamfering, rounding)

Country of Origin:

DE

Diameter External (In):

1.50

Diameter Shank:

1/4 Inch

Drive Types:

Flexible shaft drive

Drive Types 1:

Straight grinder

EAN:

4007220847367

EDP:

30188

Grit Size:

46

Item Quantity:

5

Item Weight (kgs):

0.166

MANUFACTURER_TYPE_DESCR:

W 239 6,3 AW CO 46 J5V TOUGH

Materials that can be worked:

Cobalt-based alloys

Materials that can be worked 1:

Hardened, heat-treated steels over 370 HV (38 HRC)

Materials that can be worked 2:

High-temperature-resistant materials

Materials that can be worked 3:

Nickel-based alloys (e.g. Inconell and Hastelloy)

Materials that can be worked 4:

Titanium

Materials that can be worked 5:

Titanium alloys

Max. 1-2 Inch Overhang (RPM):

12750

Optimum 1-2 Inch Overhang (RPM):

12750

Order Quanityt:

790

Prop 65:

View

Recommendations for use:

TOUGH mounted points perform best at a peripheral speed of 6,000-9,800 SFPM.

Rpm Max. 1 Inch Overhang (RPM):

9900

Safety notes:

The maximum permitted rotational speed relates to the unsupported shank length of 1/2".

Shank Length:

1.50

Shape:

W 239

UNSPNC:

23131500

UPC Code:

97758301886

Manufactured By:

Pferd Inc.

Other Details

Cool grinding due to the easily broken-down grain mixture.

High stock removal rate results in increased productivity.

The self-sharpening properties of the ceramic oxide grain provide consistent stock removal rates throughout the life of the product.

Add this new item to:

View your added items here.

Point of Sale